In respect to this, at what PSI is the safety valve set to open?

150 psi

Beside above, how do you test a air compressor safety valve? How to Test Air Compressor Release Valves

- Step 1 - Use the Air Compressor. In order to test the release valve it first needs to be under pressure. Plug the air compressor into the wall and turn it on.

- Step 2 - Locate the Release Valve. Inspect the tanks of the air compressor.

- Step 3 - Test. Grip the release valve with the wrench and pull straight out.

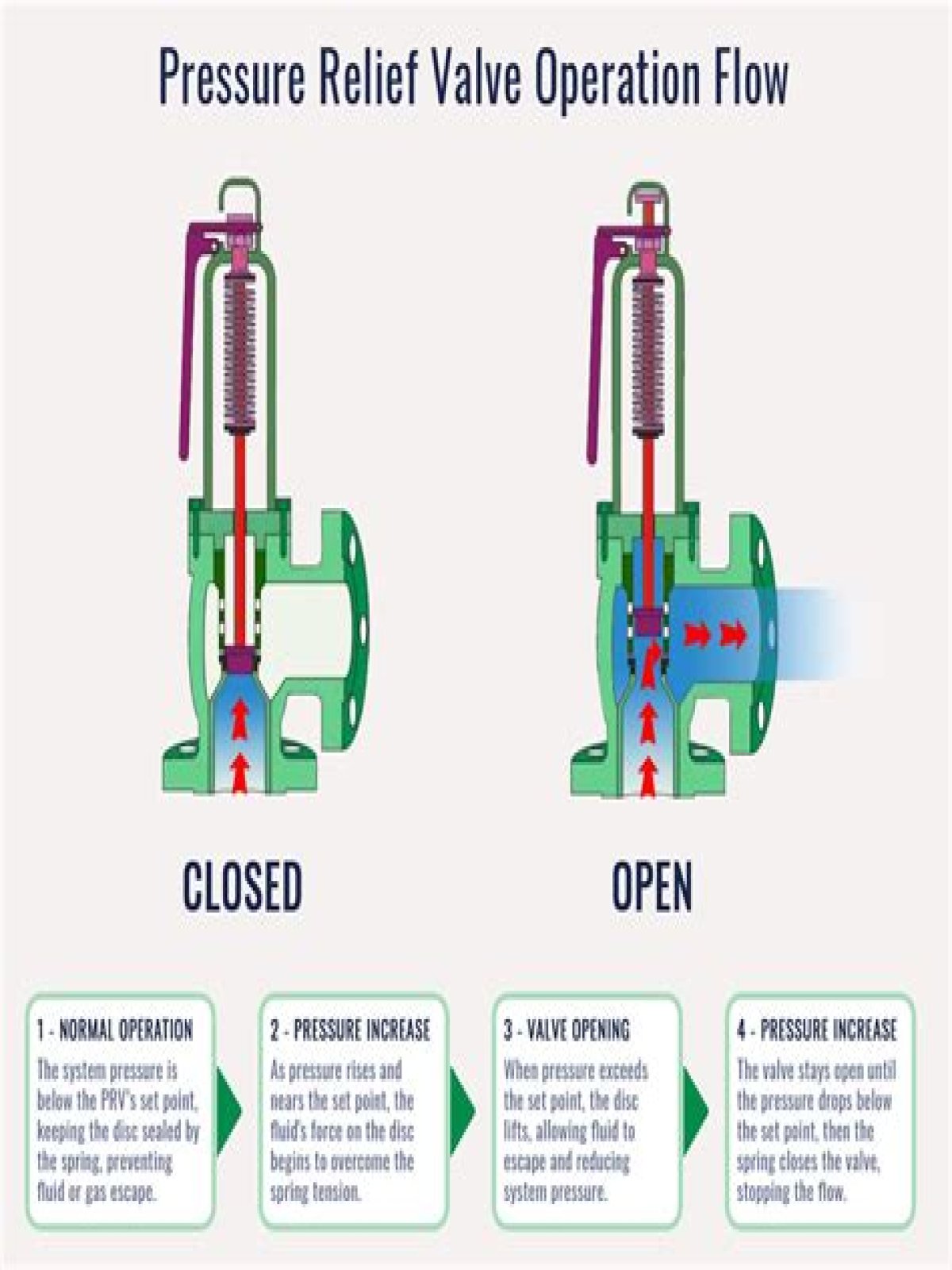

Hereof, how does a pressure safety valve work?

Pressure relief valves (safety relief valves) are designed to open at a preset pressure and discharge fluid until pressure drops to acceptable levels. When the force of the steam pressure acting on the valve exceeded the force of the weight acting through the lever arm the valve opened.

What is difference between safety valve and pressure relief valve?

The basic difference between a safety & relief valve: A relief valve relieves the pressure by relieving the fluid back into the system, to the low pressure side - eg. the relief valves of a positive displacement pump. A safety valve , on the other hand, relieves the pressure into the atmosphere i.e. out of the system.

What is cut in pressure on air compressor?

At what measurement is the safety valve set?

What is the reason that air tanks must be drained?

How long should it take to build air pressure?

What is the first thing you should do when a low air pressure warning comes on?

How fast should a truck build air pressure?

Where is the safety relief valve usually located?

What happens if pressure relief valve fails?

Do I need a pressure relief valve?

What causes a pressure relief valve to fail?

How often should safety valves be replaced?

Which is called the safety valve of nature?

How do you adjust the pressure on a safety valve?

What is creep relief valve?

How much is a relief valve?

Top Selected Products and Reviews.

| List Price: | $18.26 |

|---|---|

| Price: | $10.18 |

| You Save: | $8.08 (44%) |